Facts about printcr3dit

The project consists of three sub-projects:

Speciality chemicals: The production of special polymers for high-value products such as sports equipment, electronics, aviation and the automotive industry.

Skin care: The production of bio-based oil for application in skin care products.

Fertiliser: The production of fertiliser in partnership with Yara, the Norwegian fertiliser giant.

The three projects complement each other, in that they are all researching the benefits of 3D printing at different production scales.

Read more about Printcr3dit

Nine out of ten of the products you use every day have been through a chemical plant. SINTEF and other research institutes in Europe are now working on a project that could revolutionise the chemical industry.

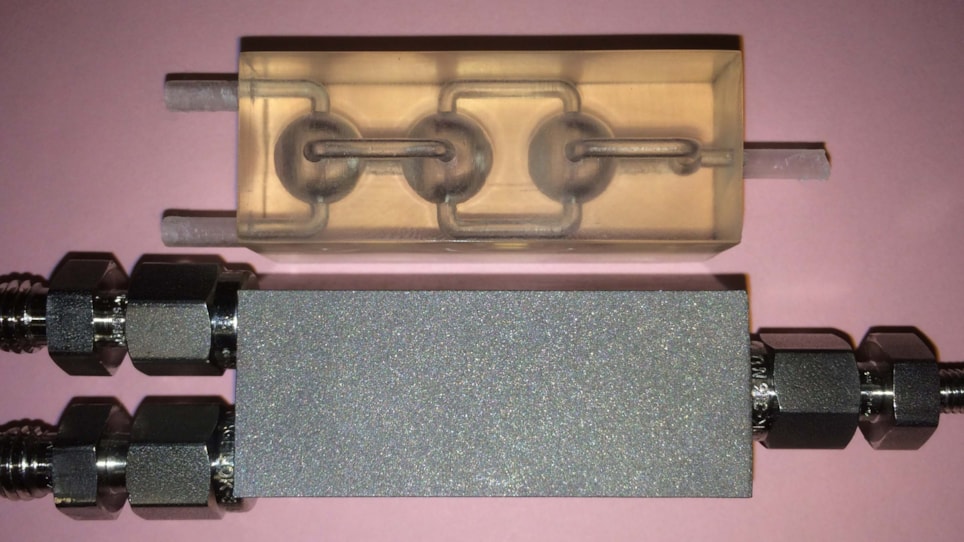

"We would like to be the architects of the future chemical, pharmaceutical and life science industries. We want to revolutionise the chemical industry by designing better and more durable reactors", explains SINTEF researcher Carlos Grande.

He is a coordinator and participant in the EU research project Printcr3dit. SINTEF is taking part as one of several research institutes that are working with a number of leading industrial companies to shape the industry of the future.

"Our aim is to make it easy to create customised equipment using 3D printing. Customising equipment using 3D printing costs almost nothing, and we avoid the price spikes that happen when we scale up production", says Grande.

He adds that the new technology also makes the catalytic reactor more environmentally-friendly, because its energy consumption is reduced in parallel with increasing its lifetime.

"3D printing means that we only use the materials we need, with very little wastage. In the chemical industry, that can also help to reduce costs significantly", says Grande.

Chemical plants are currently forced to use standard equipment and optimise variables such as throughflow, temperature and air pressure. The alternative is to use what are known as micro-reactors, but these are small and plants often need to use thousands of them.

"Their use is extremely rare in the industry. Companies who have started using these components find that their capital costs increase almost linearly, while production becomes extremely expensive", says Grande.

No chance without SINTEF and the subsidies

Yara's Odd Arne Lorentzen is looking forward to finding out what 3D printing can be used for. "I have seen several exciting examples of 3D printing applications that really work, and I'm looking forward to seeing what results we achieve from this that could be useful for Yara", he says.

The results will decide whether Yara can risk scaling up its 3D printing scheme from a small pilot operation to an industrial process. He points out that if the pilot is successful, it will be contributing something completely new. He emphasises the importance of Yara's partnership with SINTEF, and the generous subsidies that enabled Yara to try out this untested technology.

"I would like to hope that this could help to improve the industry and make it more competitive. Hopefully we will get our answers during the next year, but we need the tests to yield good results, since it will involve a huge financial and technical risk for Yara to scale up from a pilot scheme to an industrial process", says Lorentsen.

Three subsidiary projects

"At the moment, we are limited by the size of the printers available, but development in this field is moving exponentially, and every day brings new improvements", says Grande.

"No one asks the architects how the building was made or what construction methods were used. What matters is who the architect was. This is where we want to be in our industry", believes Grande.

He envisages that the results achieved in the chemicals industry could also quickly be utilised in other areas.

We are in the process of adopting similar strategies in the field of life sciences, with the aim of purifying virus-like particles so that they can be used in targeted vaccines. We believe that 3D printing could also result in a breakthrough in this industry", says Grande.

Norwegian version, click here